Evaporative Ammonia Condensers

we provide high-performance Evaporative Ammonia Condensers, designed to offer efficient and reliable heat rejection solutions for industrial refrigeration, food processing, cold storage, and HVAC applications. These condensers utilize the power of evaporative cooling to enhance heat transfer efficiency while minimizing energy consumption and operational costs.

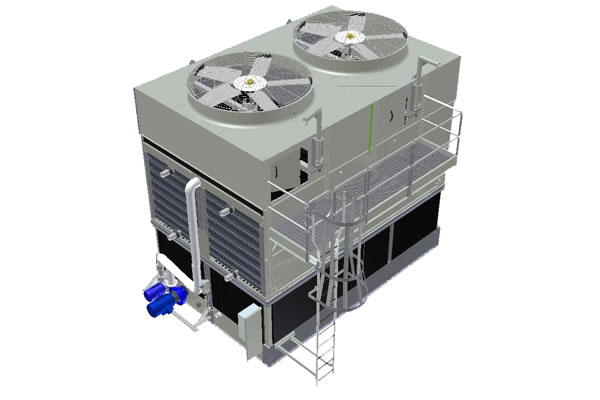

We offer Ammonia based Condenser Evaporative Type that are made with robust mild steel, C class ISI ERW Tubes with water storage tanks and electrical axial flow fan. The condensers are available in different capacities and fabricated with spray galvanizing. Our evaporative condensers are utilized for following purposes

Our Evaporative Ammonia Condensers operate by passing hot ammonia gas through a heat exchange coil, where water is sprayed over the coil while air is drawn through the unit. As the water evaporates, it removes heat from the ammonia, condensing it back into a liquid state. This process significantly improves cooling efficiency compared to air-cooled or water-cooled systems.

we offer custom-engineered Evaporative Ammonia Condensers tailored to meet the specific needs of various industries. Our solutions are designed to enhance cooling efficiency, reduce environmental impact, and ensure long-term operational reliability.

Key Features

- High Energy Efficiency – Reduces power consumption by utilizing natural evaporative cooling, lowering operational costs.

- Superior Heat Transfer – Enhanced coil design ensures maximum heat dissipation, improving overall system performance.

- Compact & Space-Saving Design – Requires less space compared to traditional cooling towers and condensers.

- Eco-Friendly Operation – Uses less water and energy, contributing to a more sustainable and environmentally friendly cooling solution.

- Corrosion-Resistant Construction – Built with durable materials to withstand harsh industrial environments and ensure long-term reliability.

- Low Maintenance & Operational Costs – Designed for easy cleaning and maintenance, reducing downtime and ensuring smooth operation.

Applications

- Ice Plants

- Cold Storages

- Dairy Industry

- Breweries Meat / Fish Processing

- Food Processing Plants

- Quick Freezing Plants

- Chemical / Petrochemical Plants

- Food & Vegetable Freezing Plant